Copper Rod Casting Line

copper rod continuous casting machine

Time:2020-05-29 13:21

Middle East Customer satisfied oxygen-free copper wire making machine copper rod castercopper rod caster

1. Parameters of copper rod casting machine

|

No.

|

Item

|

Data

|

|

1

|

Annual capacity

|

100tons – 12000 tons

|

|

2

|

Furnace structure

|

3 body (2 melting, 1 holding )

|

|

3

|

Casting Strands

|

2 – 24

|

|

4

|

Casting rod diameter:

|

8mm- 35mm

|

|

5

|

Upward casting speed

|

0-3000mm/min

|

|

6

|

Annual working time

|

7920 h

|

|

7

|

Liquid tracking precision

|

±2mm

|

|

8

|

Take-up coil standard

|

700mm×1500mm×800mm

|

|

9

|

Copper melting velocity

|

160 – 520 kg/h

|

|

10

|

Copper melting power consumption

|

<350 kwh/ton

|

|

11

|

Take-up form

|

Automatic adjust

|

|

12

|

Take-up plate driven approach

|

inverter motor, PLC control

|

|

13

|

Material feeding method

|

whole piece of electrolytic copper cathode fed by electric hoist

|

|

14

|

Upward driven approach

|

Driven by the AC servo motor, transmission chain is driven by the gapless synchronous cog blet

|

|

15

|

Rod clamping method

|

Air clamping

|

2. Main equipment of copper rod casting machine

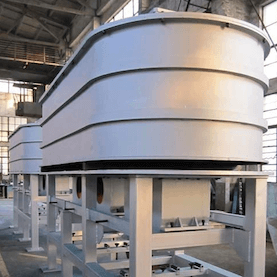

2.1.Line frequency induction furnace

Water jacket and coil all need to be cooled by water, the water can be recycling used, and is supplied by the cooling water system.

2.2.Continuous casting machine

2.3.Output frame

2.4. Water cooling system

2.5. Double head take up machine

The line frequency induction furnace includes furnace body, furnace frame and inductor.The shell of the furnace is made of welded steel, inside part is made of casted refractory brick and quarts sand. Furnace frame is used for propping up the whole furnace, it is fastened on the foundation by ground bolt, inductor composed of coil, water jacket, iron core and copper channel.The high voltage side of the inductor(primary) includes coil with cooling water, the voltage could be adjusted form 90V-420V(holding furnace is 90V-380V), the low voltage side of the inductor(secondary)includes short circuited copper channel, after electrifying, it will produce big current in copper channel with the action of electromagnetism induction, and melt the copper channel and also melt the cathode at the same time .

The main part to realize the continuous upcasting which includes the traction system, the level tracking system and the crystallizer, the structure is gantry four pillar.The output frame is set up on the upper part of the casting machine. It includes the platform, the support, the vertical guide wheel and roller. It separates and feed the casted rods into each double head take up machine without influencing each other.The water cooling system is an independent water recycling system which supplies the cooling water for the crystallizer, the water jacket and the induction coil.

It includes one 200M2 water pool, water pump, pipelines and the cooling tower. It insures that the inlet water temperature is around 20-35℃, the flow rate is about 50m3. For a good heat exchanging effect, the user need to prepare the water soften device.The double head take up machine includes the traction roller, the coiling device and the coiling plate. Each unit of the take up machine includes four or three motors controlling the two sides of take up device for two rods, the max coiling weight is 3.5ton.

2.6. Electric control system

Middle East Customer satisfied oxygen-free copper wire making machine copper rod caster

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Tel: +8615000437616

Whatsapp: +8615000437616

Wechat: +8615000437616

Email: enquiry@shsinopower.com

Shawn Xu

Shawn Xu Shawn Xu

Shawn Xu